Automated Optical Inspection (AOI) Solutions made for you !

No matter what specific requirements you have, our inspection solutions will help improve yield and quality

Looking for Reflow-Furnaces ?

Stratus Vision at the Productronica China

Visit our booth at the Produtronica trade fair in Shanghai (20-22nd of March), where we will be unveiling cutting-edge inspection systems for wire bonding and photomask inspection.

Building Successful Solutions Since 2003

Our technology is patented and allows us to offer amazing inspection solutions throughout the most complex of requirements.

Almost all of our system use the same powerful software package called SPIN, that lets engineers easily set up new products within minutes.

Our Core Competenices

Inspectable Materials and Applications:

- Ceramic Multilayer Hybrids

- LTCC

- HTCC

- Sensors

- Interposers

- Wirebond

- Reticles

- Wafer

- LDI

- PCB

- DBC

Defects Types:

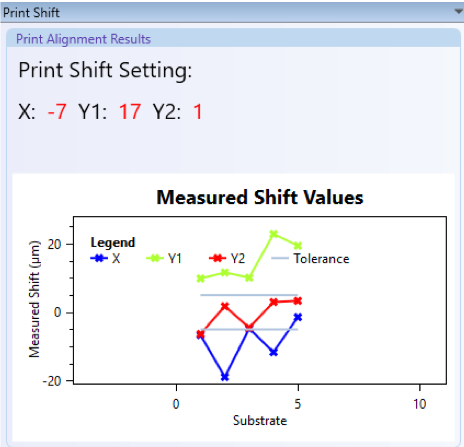

- Print shifts

- Scratches

- Finger prints

- Screen aging

- Excess Paste

- Missing Paste

- Contamination

- Screen defects (holes)

- Wrong Screen

- Substrate shrinking (LTCC)

- VIA: Wrong position or diameter or non circularity, not filled

- Ditches (divots) or elevations

AI Analysis:

- First Algorithm based defect categorization

- Categorization reliability of 99,5 %

- faster root cause detection

- Available as Software-Option for third party AOIs

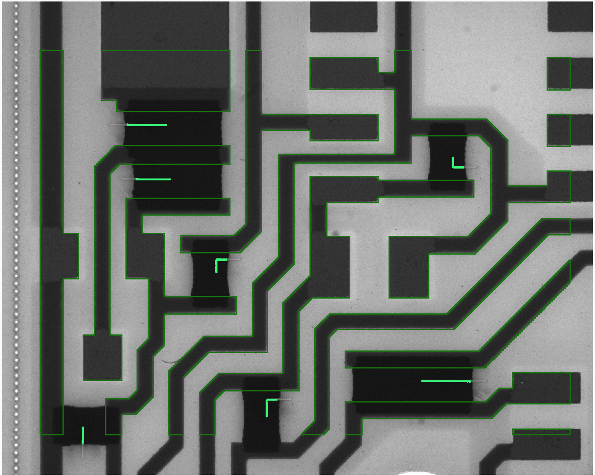

The STRATUS solutions are the best choice on the world market for the in-line inspection and offline inspection of unpopulated structures like multilayer hybrids, LTCC/HTCC, Wafers, Chrome masks and other screen or stencil printed, electroplated or sputtered structures. In-line inspection, where the structure is inspected directly after the manufacturing process, is the best way to ensure quality and increase yield. But also finished, or partly finished, substrates can be inspected very well with the STRATUS solutions.

The Right Choice

Making an Impact Across the Globe

Having customers and partners in all major markets around the globe we have been able to support production of the most innovative technology products. From Automotive, Consumer Electronics to Pharmaceuticals our customers produce leading technology.

We want to always be at the forefront of technology with our products, while offering an efficient and at the same time pleasant, productive working environment for our employees. At the same time, we strive for quality and growth.

We maintain a close, collaborative relationship with our suppliers and other partners. Our valued customers, however, are always at the forefront of our commitments and priorities – they can always count on us!

With our customers, we aim to make perfect use of the latest technologies and applications on a basis of close trust.

The STRATUS VISION AOI Systems will find typical defects (on wet or dry layers):

– Print shift

– Scratches

– Finger prints

– Screen aging

– Excess paste

– Missing paste

– Contamination

– Screen defects (holes)

– Wrong Screen

– Substrate shrinking (LTCC)

– VIA: Wrong position or diameter or non-circularity, not filled

– Ditches (divots) or elevations

In- and Off-Line Inspection as well as any degree of automation can be delivered. The Inspection process itself is always automatic, even on systems that are manually loaded/unloaded.

Our AOI-Applications

Laser Trim Inspection

Learn more about the automated Laser Trim Inspection for screen printed resitors

Print Shift Inspection

Learn more about the automated print offset calculation of ceramic hybrids, LTCCs, HTCCs and many more

SPIN Software

Learn more about the Stratus Vision SPIN Software

Customized Application

We are always eager to extend the functionality of SPIN. Let us know how we can optimize your inspection process !